Mit-ivy industry metal Advanced Acrylic Latex Sealing Primer b'qawwa penetranti eċċellenti

Applikazzjoni

Għandu adeżjoni eċċellenti ma 'sottostrati ta' l-azzar u primers simili bbażati fuq l-ilma, u proprjetajiet fiżiċi u mekkaniċi eċċellenti wara li l-mewġa taż-żebgħa tinxef.

5. Il-film taż-żebgħa għandu preservazzjoni tad-dawl eċċellenti u preservazzjoni tal-kulur wara t-tnixxif.

Applikazzjoni rakkomandata Huwa adattat għall-protezzjoni tad-drenaġġ ta 'trakkijiet, partijiet tal-makkinarju, tagħmir industrijali ħafif, eċċ. Fejn hija meħtieġa protezzjoni għolja.

Dejta teknika Kulur assortit

Niexef fil-wiċċ (50% ta 'miscibility) 15 ℃ C <1h ; 25'C <0.5h

Niexef solidu (umdità ta '50%) 15'C <48h; 25 ° C <24 siegħa

Hits "kg.cm" 50

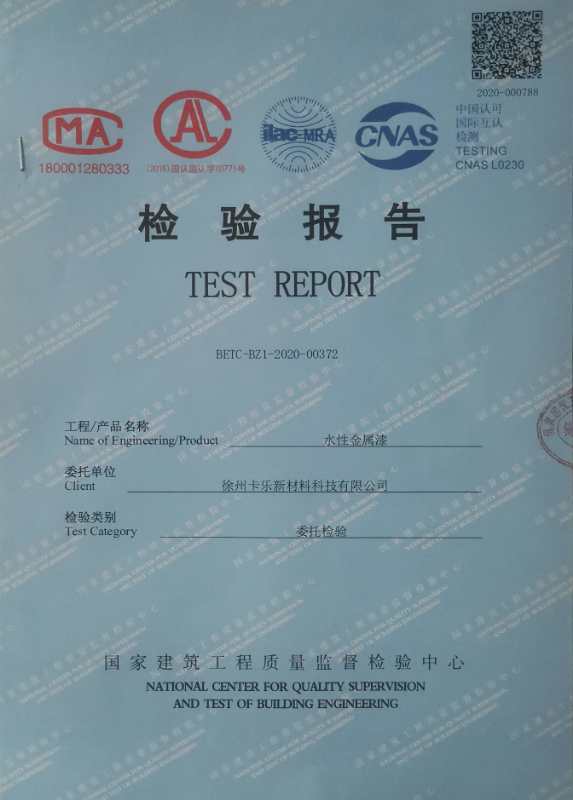

Ilma (50 ± 5μm) 72h film taż-żebgħa ma joħroġx folja, ma jgħinx jaqgħu, mhux sadid.

Ebusija 0.3 (pendlu doppju) ħxuna tal-film tal-ittestjar tal-proprjetà mekkanika (23 ± 3jμm)

Adeżjoni (Hegelian) Livell 1

Trattament tal-wiċċ Il-wiċċ tal-materjal miksi għandu jkun ħieles minn umdità, żejt, karbonu aċiduż u rmied.

Dettalji ta 'malajr

Azzar b'ġilda ta 'ossidu: Shot blasting jew metodi ta' blasting tar-ramel bħall-ipproċessar għal-livell Sa2.5, fejn l-ibblastjar tar-ramel ma jistax isir għandu jkun illustrat b'mod mekkaniku jew

Ittrattat kimikament biex tneħħi l-ispallejn miksura kollha li jżommu f'wiċċ l-ilma.

Azzar mingħajr ġilda ta 'ossidu: ibblastjat bir-ramel (ibblastjat) għal Sa2.5 jew għodda elettrika għat-tħin bl-arja għal St3.

Iwweldjar, qtugħ ta 'fjammi jew korrezzjoni ta' logħob tan-nar ta 'żoni ta' ark maħruq: tħin sal-livell St3.

Materjal bażi b'film ta 'żebgħa qadima: neħħi l-partiċelli ta' żebgħa qodma maħlula u s-sadid, u ramel għal St3 b'għodda ta 'xkatlar bl-arja jew bl-elettriku.

Pakkett tipiku ta 'żebgħa jista' jintuża ma 'primer ibbażat fuq l-ilma H902, jew użat waħdu bħala kisja dekorattiva ġenerali, jew użat ma' tipi oħra ta 'prodotti ta' primer (jeħtieġ li jiġu mqabbla għall-verifika).

Construction data Table dry (50% temperature) 15'C<th;25℃C<05h Actual dry (50% humidity) 15℃C<24h;25℃<12h Density about 1.1-1.20g/cm' Theoretical coating rate 0.15-0.2kg/m' (dry film 40-50) μm)

It is recommended to apply 2 coatings, which can be applied in the way of warm touching temperature to ensure that the dry film is 40-50μm.

To be sanded and finished with sandpaper.

Construction method Air or robot spraying is possible. Mix the paint before use, adjust the viscosity according to the construction method.

Add 5-15% of water. Add water and stir evenly, then leave the surface to work without bubbles.

Construction environment 1. The brain playground should have good ventilation and dust removal facilities to ensure the quality of construction.

2. The construction should be carried out under the condition that the mixing degree is above 5℃C and the relative humidity of the environment should be <70%.

3. The substrate temperature shall be not less than 5' and shall be more than 3'C above the air dew point temperature.

washout

| Vehicle Type | 100% Acrylic Latex | |

| COMPOSITION (nominal) | Pigment : Lightfast Non-Lead Pigments & Mineral Extenders.

Blinder : Acrylic Emulsion. Solvent : Water. |

|

| Volume Solids | 31.8% | |

| Coverage per Gallon at Recommended Film Thickness | 400 –450 Sq. Ft. (37-42 m2) | |

| Recommended Film Thickness

(Depending on surface texture and porosity. Be sure to estimate the right amount of paint for the job. This will ensure color uniformity and minimize the disposal of excess paint) |

Dry 1.2 mils

Wet 3.8 mils |

|

| Dry Time @ 77° F (25° C) @ 50% RH

(High humidity and cool temperatures will result in longer dry, recoat and service times.) |

To Touch 1 Hour

To Recoat 2 to 4 Hours |

|

| Dries By | Evaporation, Coalescence | |

| Viscosity | 99 ± 2 KU | |

| Gloss / Sheen | Flat (5-10 @ 85°) |

| Shipping time by Sea (Just for reference) | ||||||||

|

North America |

11~30 days | North Africa | 20~40 days | Europe | 22~45 days | South-east Asia | 7~10 days | |

| South America | 25~35 days | WestAfrica | 30~60 days | MiddleEast | 15~30 days | East Asia | 2~3 days | |

| Middle America | 20~35 days | EestAfrica | 23~30 days | Ocenia | 15~20 days | South Asia | 10~25 days | |

FAQ

1.About Sample

We provide free sample for testing.

2.OEM,ODM service available.

3.According to customer's request, packed with pallet or without pallet.

Tile adhesive(20kg/bag)packing with pallet specification:

64 bags/pallet = 1.28 MT/pallet

72 bags/pallet = 1.44 MT/pallet

One full 20ft container max loading 27.6MT.

With pallets can load 1360 bags, without pallet can load 1380 bags.